- Name: Material Test Diffractometer

- Technique: Neutron Diffraction

- Range of investigated features: Crystal and magnetic structure with d-spacing up to several angstroms (Å)

- Penetration depth: Several millimetres, dependent on energy-distribution of the incident neutrons and sample-properties

- Typical size of sample: 1.25 or 2.5 cm3 is required in optimal case

- Measurable materials: Amorphous, Crystalline and Liquids

- Contact: mtest@bnc.hu

The Material-TEST (MTEST) is a general-purpose 2-axis diffractometer with medium resolution. The instrument comprises three monochromators: Cu (111) for maximum flux, Cu (220) for wide Q-range, and Ge (111) for better resolution. The wavelength range (λ) covered is 0.89 – 1.45 Å. A Variety of samples can be studied, such as amorphous materials like glasses and liquids, polycrystalline samples etc. The instrument can be utilized to investigate both short range and long range ordered correlations via total (diffuse) scattering together with Bragg diffraction. The maximum neutron flux obtained at sample position is 2 × 106 neutrons/cm2sec for 1.33 Å wavelength. The standard cylindrically shaped vanadium sample cans (6 and 8 mm in diameter) are used for the experiments. With automatic sample changer 4 samples can be loaded together and measured at room temperature. The current sample environment capabilities include a high temperature low background Vanadium vacuum furnace (RT – 973.15 K) and closed cycle refrigerator (10 – RT K). The scattered neutrons are detected by a 3He-detector system placed in three well-shielded banks, with the best instrumental resolution of ~ 0.6°. The collected dataset is calibrated using standard procedure. The obtained data files can be used for further analysis such as pair distribution function analysis, reverse monte carlo simulations and Rietveld refinement.

The MTEST is a two-axis, medium resolution neutron diffractometer. The instrument is installed on axial thermal channel no. 6 at the 10 MW Budapest Research Reactor facility. To filter out epithermal neutrons, a sapphire single crystal deep inside the beam shutter is used. MTEST is equipped with three monochromators Ge(111), Cu(111) and Cu(220). These are placed on a mechanically rotating drum, mounted in a vertical plane between the primary and secondary collimator. The 3 monochromators extend the possibility to optimize the neutron beam for high flux, wavelength, wide Q-range and / or resolution (~ 0.6°) based on the experimental requirements. The details pertaining to this are given in Table 1 below. The diffractometer is equipped with air cushions to achieve the necessary flexibility for a continuously variable wavelength. The monochromator take-off angles may be set between 28° and 54°, varying the wavelengths between 0.65 Å and 3.5 Å. However, most of the time the take-off angle is fixed at 40°. The wide flexibility of instrument parameters allows MTEST to be a highly versatile instrument capable of addressing samples in areas ranging from amorphous materials, i.e. glasses and liquids, to disordered crystals and medium resolution crystals.

Table 1.: Illustrative instrument parameters for typical samples

| Sample types | Monochromator | Wavelength [Å] | Q-range [Å-1] | Intensity |

| Disordered crystal | Cu(111) | 1.45 | 0.35-8.2 | 100% |

| Medium resolution crystal | Cu(220) | 1.35 | 0.4-8.8 | 40% |

| Liquid/amorphous | Cu(111) | 1.11 | 0.45-10.7 | 85% |

| Medium-Q liquid/amorphous | Cu(220) | 0.89 | 0.55-13.3 | 10% |

| Low-Q liquid/amorphous | Ge(111) | 2.27 | 0.25-5.2 | 6.5% |

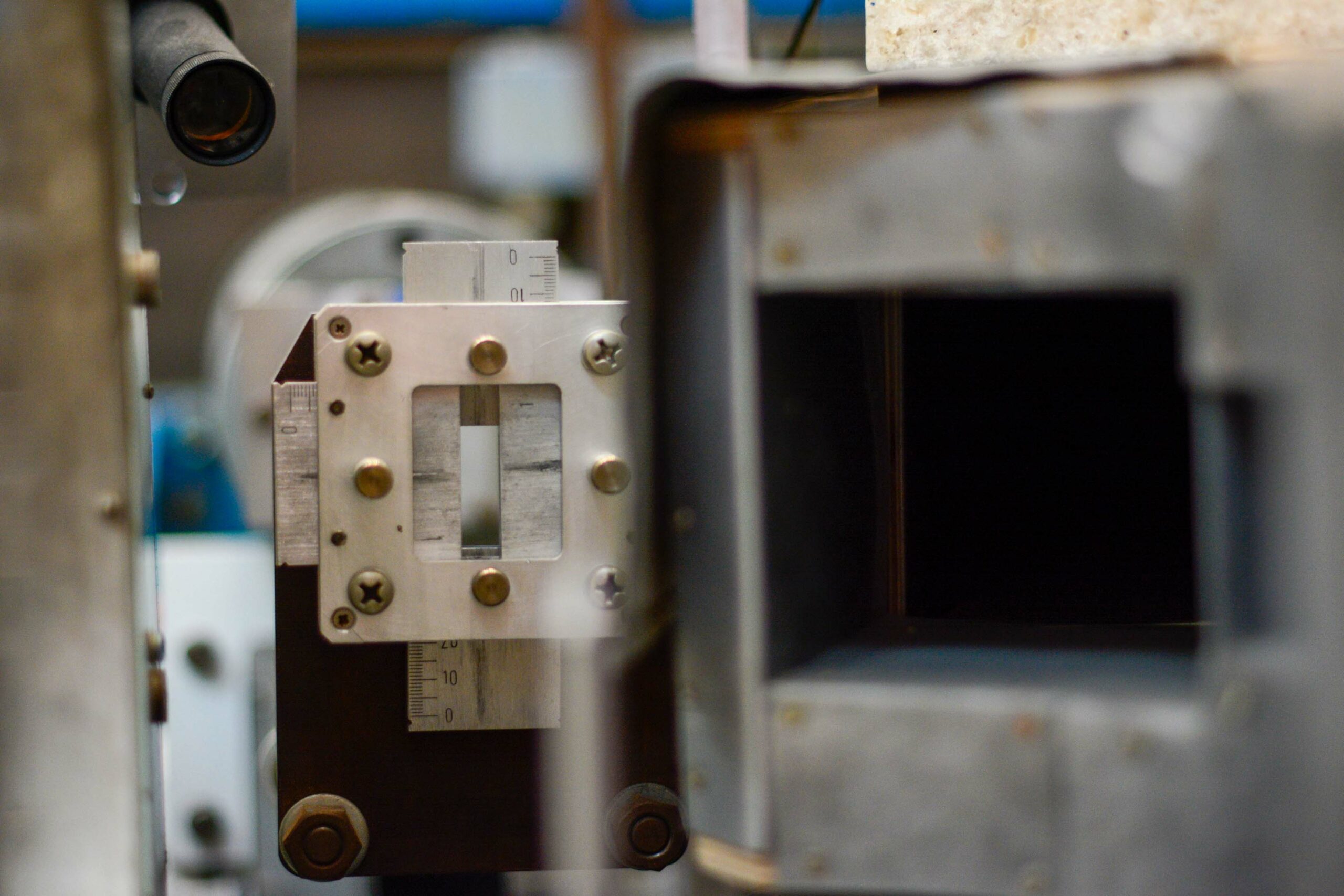

A low efficiency fission chamber as a monitor counter is used to measure the intensity of the incoming beam. The maximum neutron flux obtained at a neutron wavelength of 1.33 Å, is of the order of 2 × 106 neutrons/cm2 sec. The standard beam size is 10 mm (width) x 40 mm (height), which can be adjusted by slits to the required size. The standard Vanadium sample cans (Diameter: 6 and 8 mm, Length: 50 mm) are used to record neutron diffraction pattern. The estimated sample amount of 1.25 or 2.5 cm3 is needed in optimal case. At the sample stage, an automatic sample changer (sample displacement in X – Y plane) is available with the possibility to load 4 samples together for room temperature measurement.

The scattered neutrons are detected by a set of position sensitive 3He detectors assembly. The detector assembly consists of well-shielded three 3He detector banks placed precisely in the air chamber. The low angle bank contains 3 pieces of 1-inch and 1-piece of ½-inch diameter, whereas the high angle bank contains 5 pieces of 1-inch diameter, 60 cm long Reuter-Stokes linear position sensitive. The typical distance between the 3He-detectors and sample is 80 cm, covering ± 19.6°. In the middle bank, an Ordela 2-inch high, 20 cm wide linear position sensitive 3He detector is installed 78 cm from the sample, covering ± 6.85°. The entire arrangement allows to record the total scattering powder diffraction pattern from 4.5° to 142.6° on 2θ-range. The data is measured at two positions i.e. 24.5° and 57.5° and the best achievable resolution is ~ 0.6°.

The current sample environment capabilities include a high temperature low background Vanadium vacuum furnace (RT – 973.15 K) and closed cycle refrigerator (10 K – RT). The standard data calibration measurements are performed using Ni powder at the beginning of every reactor cycle. The obtained data also is corrected for absorption, detector efficiency and background (air and Vanadium can) using a code written in python program. The final data file is obtained in a simple readable format. For relevant data interpretation, further fitting analysis based on Rietveld refinement or reverse monte carlo techniques can be performed.